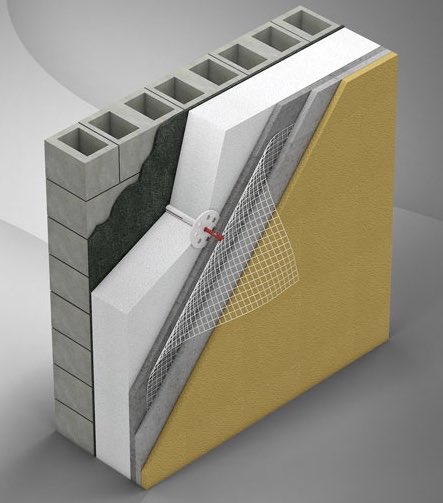

An external insulation finishing system (EIFS) is a type of cladding that provides exterior wall facades with an insulated finished surface that is applied in multiple layers over the exterior liner (cement block) as an energy-efficient, fire-resistant, low-maintenance, beautiful, and versatile exterior enclosure .

System applications:

It is used to insulate external walls and also as an acoustic barrier against fire and shock.

The external insulation system (thermal coat) prevents water from reaching the main pillar of the wall. .

It provides a layer to increase crack and heat resistance.

It protects against cracking and collapse due to shifting foundations, thermal expansion and freezing cycles. .

It acts as a barrier to weather effects (thermal insulator).

The finishing coat provides the colour, texture and protective nature of the outer surfaces of structures.

Used in the interior and exterior walls of the building.

Used as an expansion joint in connected buildings.

Contributes to the rehabilitation of old buildings and the improvement of their facades.

It is also used in achieving external architectural decorations in several models.

Advantages:

Identify the EIFS

1- Light weight.

2- Ease of transportation in large quantities covering excellent areas.

3- Saving transportation costs.

4- The speed of completion.

5- Preserving the cohesion of the walls in case of vibration resulting from natural factors such as earthquakes.

6- Complete thermal insulation from heat and moisture.

7- Its presence in multiple measurements as desired.

8- The possibility of using any material in the final cladding layer.

9- Shock resistant.

10- Sound insulation.

11- Water insulator.

12- Economically feasible.

Implementation method:

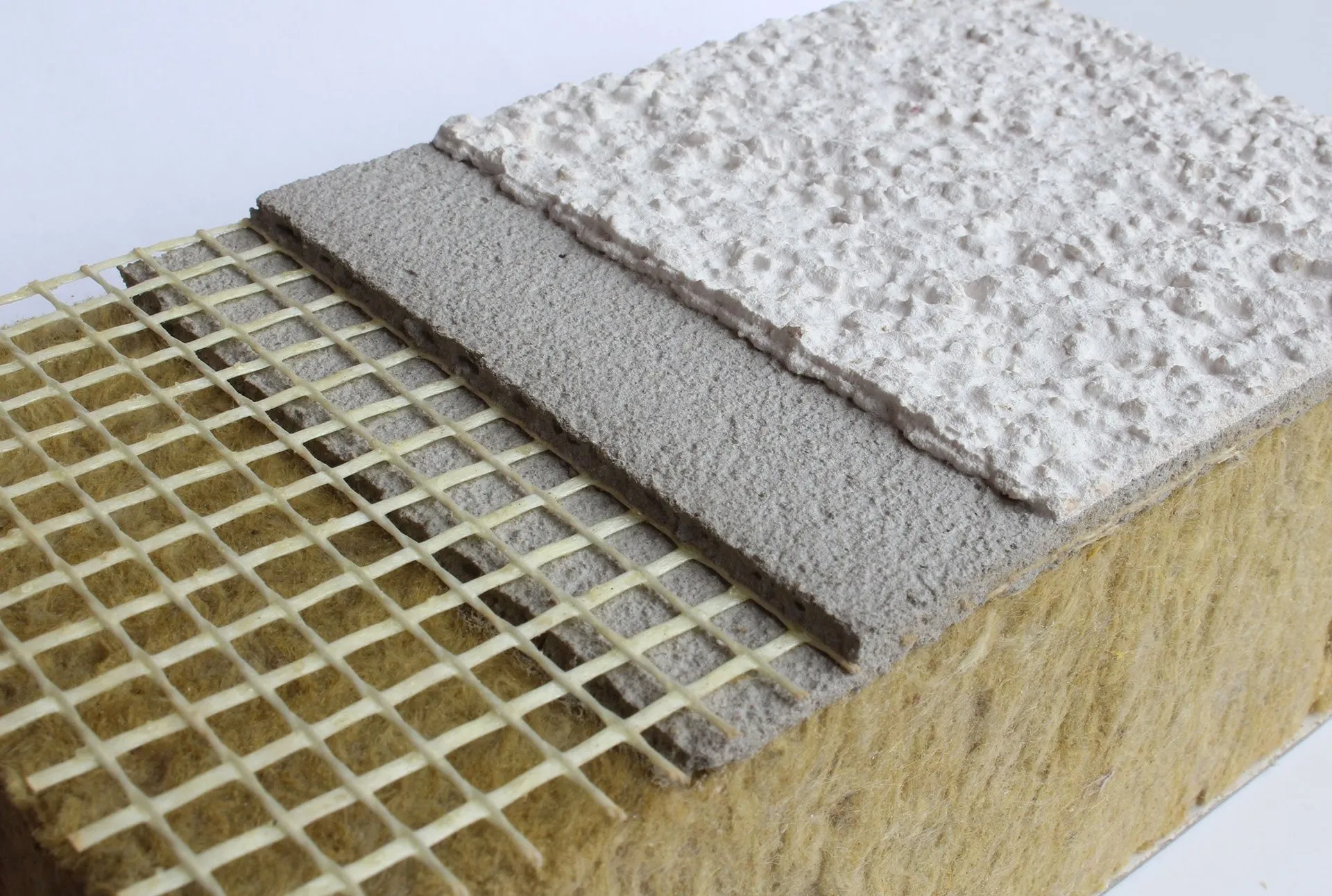

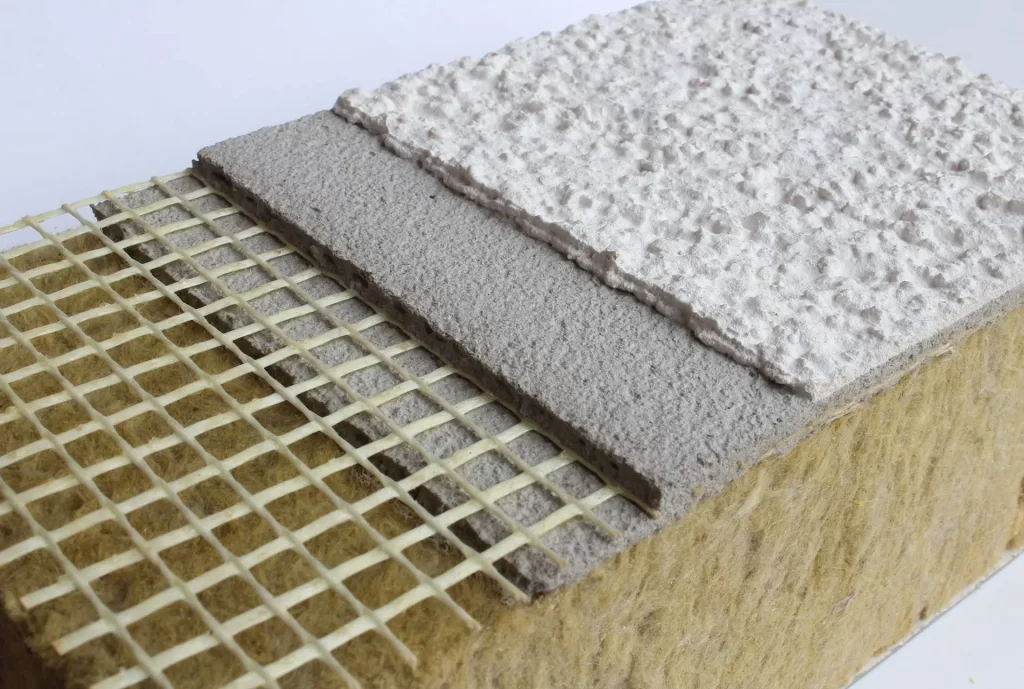

1- A cement base layer is applied to stick the stereo board on the cement block.

With a simple thickness of about 2 mm.

2- The stereo board is directly fixed to the cement layer, and it needs 24 hours to solidify.

3- After that, a cement base layer of 1-2 mm thickness is completely laid over the slab.

4- Applying fiber mesh over the entire board, then waiting for the base layer to solidify for 24 hours.

5- Applying a final cement layer with a thickness of 1-2 mm.

6- Implementation of the final cladding layer.